It has a 1.2m x 180mm 12% chord Armin wing and a 700mm fuselage both made from 6mm depron covered with 75 micron document laminating film. That is the thicker laminate and it added lots of strength.

I also wanted to try a design with the tail as part of the fuselage, and test a full flying elevator setup. Both are working very well so far.

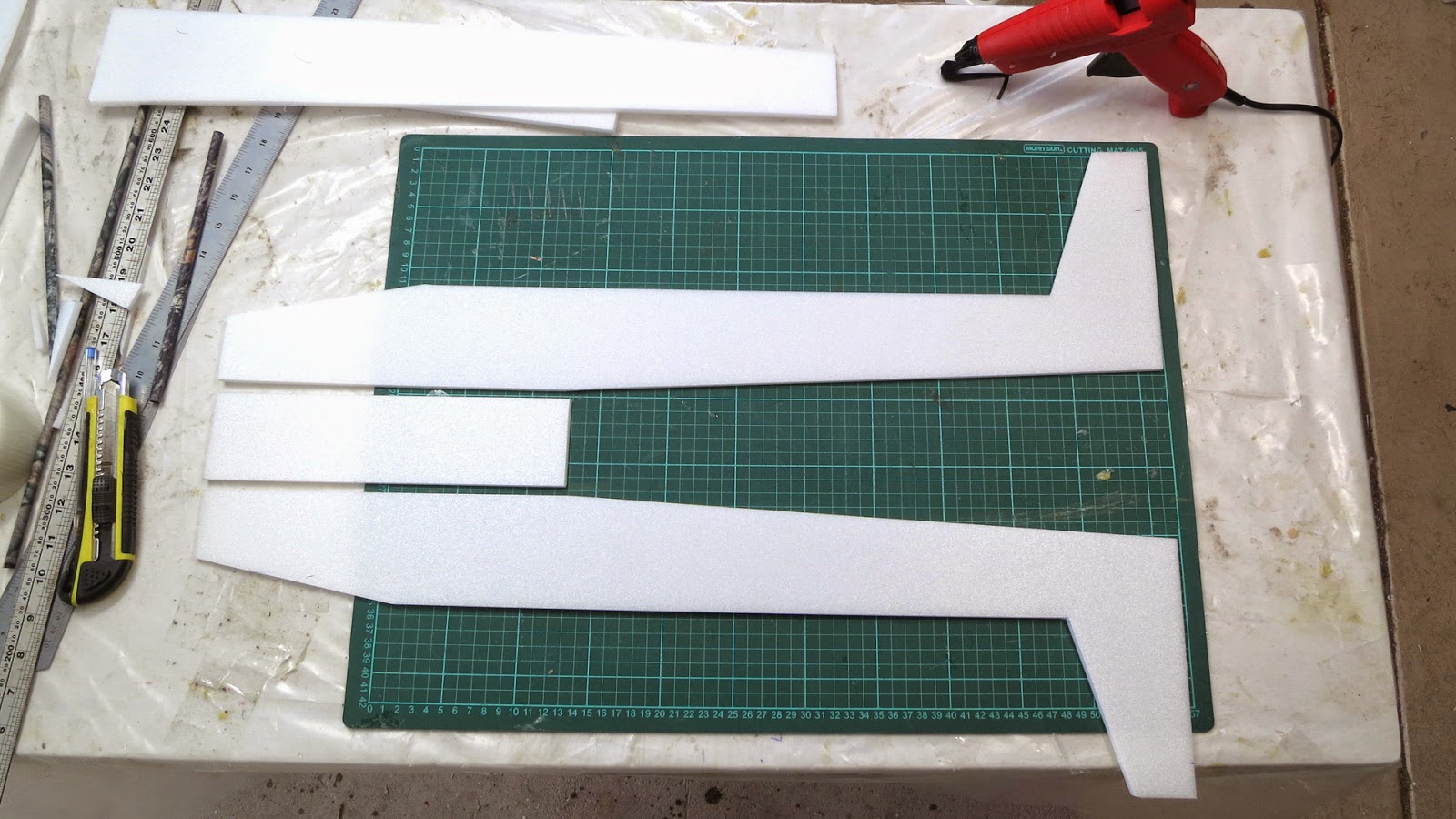

Fuselage construction started with the side and bottom panels in uncovered depron

The sides were glued on top of the bottom panel, which defines the width of the front area.

The tail halves were glued together giving the taper curve, then top and bottom panels added.

The fuselage was then covered with 75 micron laminate.

This added a great amount of strength, especially to the narrow tail area.

The 2826/10 1400kV motor is mounted to 5mm plywood with ventilation holes drilled out. Initially I built in some down thrust but I am still testing to find the right amount. Plastic washers can be added or removed to vary the angle.

The most radical feature of this design is the flying elevator. The whole horizontal stabiliser pivots on a 3mm carbon fibre rod which also acts as the spar. The rod passes through a brass tube glued into the tail. The inner diameter of the brass tube must be just bigger than the CF rod to give free movement but minimal wiggle. To hold the brass tube firmly there are 25mm discs of foam sandwiched between ID card plastic on either side.

Plans

Overview and build video

Field and slope flights

SPECS

Armin wing span - 1.2m (47")

Airfoil chord - 190mm (7") including 45mm (1.5") ailerons

Airfoil thickness - 23mm (12%) using 9mm formers

Spar - Skyshark P4X 7.5mm x 850mm, 57mm back from LE

Fuselage Length - 700mm (27.5")

Flying weight (2200mAh LiPo) - 770g

Full span Ailerons / Flaperons

Full flying Elevator

Large Rudder

TGY 9018MG servos x 4

Motor - Turnigy 2826/10 1400kV with 8x4 prop

ESC - Plush 40A

MATERIALS and LINKS

ESC - Plush 40A

MATERIALS and LINKS