It will work in anything over 5kn on a decent slope and in 10kn it will work on any slope.

The rudder and elevator are operated by a pull line acting against a torsion spring.

This unique system means the servos can be forward in the fuselage and there are no pushrods going to the tail.

The trick is to make a torsion spring strong enough to operate the control surface against the airflow

The trick is to make a torsion spring strong enough to operate the control surface against the airflowbut not so strong as to overpower the servo.

The 0.4mm SS wire provided as pushrods for the Versus DLG turns out to be perfect.

SPECS

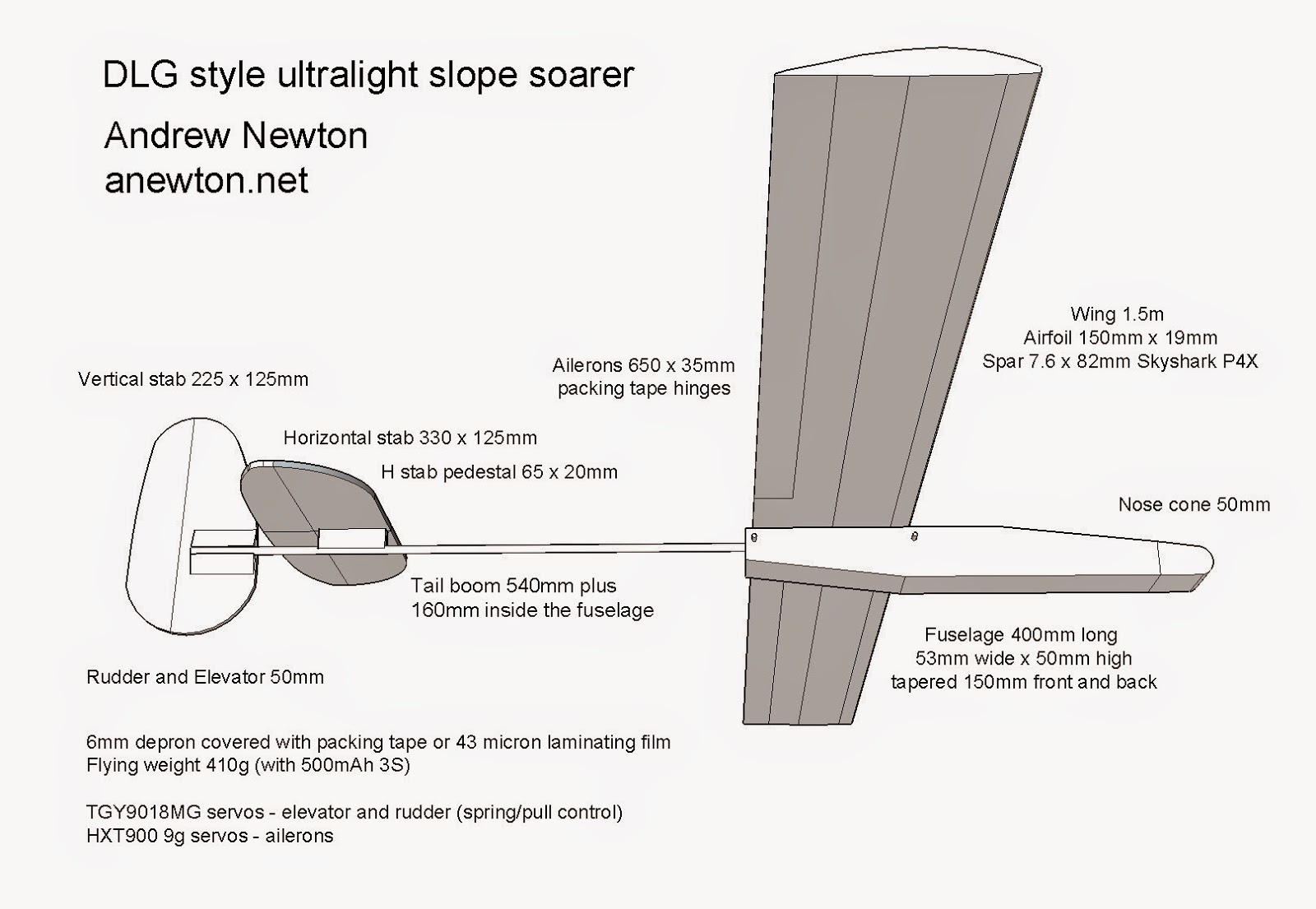

Wingspan - 1.5m (65") Armin wing

Length - 104cmm (38")

Flying weight (500mAh LiPo) - 410g

Ailerons

Elevator

Rudder

TGY 9018MG servos x 2 (elevator and rudder)

HXT900 servos x 2 (ailerons)

MATERIALS

6mm depron

43 micron laminating film

60 micron clear packing tape

2 x Skyshark P4X spars (7.6mm x 820mm)

- Wing spar 820mm

- Tail boom 700mm

150lb Kevlar kite line (pull line)

0.4mm SS wire (torsion springs)

Soft packing foam (nose cone)

4mm CF rod (wing tie down bars)

Overview and build video

Aerobatics in 10kn

Testing with dihedral and no ailerons

Skyshark P4X spars - http://www.kitesandfunthings.com/ProductInfo.aspx?productid=SSP4XCAM0

New Stuff iron-on film - EZload laminate - GBC Australia

Blank ID cards - Ebay http://www.ebay.com.au/usr/y2store?_trksid=p3984.m1439.l2754

UPDATE March 2015: On really hot days the rudder and elevator servos have moved out of position as the glue softened. I have added more foam packing and glue to fix them securely. The trailing edge of the wing has also popped open twice. I removed the ailerons, re-glued then taped the join, then reattached the ailerons. In the original build, by cutting out the ailerons from the wing, I removed too much of the glue holding that join.

Thanks Andrew. As so often these days, you provide exactly what I need . Regards, Ian

ReplyDeleteMy pleasure Ian.Good to know someone is reading this.

Deleteyou have followers from Turkey too,dont worry Andrew :)

ReplyDeleteGreetings Burak,

DeleteThanks, I'll keep posting.

Greetings from NZ Andrew. Im going to have a shot at this as my first build ever. Perhaps without the ailerons. Do you think it would still perform well without the ailerons?

ReplyDeleteHowdy. You would need wing dihedral if you're not having ailerons, but it should be OK. Easy enough to add ailerons afterwards anyway. I'll be interested to hear how you go.

DeleteUse ailerons anyway: dihedral is fine, but for that little bit of extra effort pilots get a lot more, and finer graduated control with ailerons.

DeleteI tested this today in a decent 15kn. Locked off the ailerons and swapped the straight spar for one with dihedral. With the left wing flat the right tip was 120mm raised (1.5m wing) It flew easily but was very slow to turn. A bigger rudder control surface would fix that. Made it very docile and smooth, but at the expense of aerobatics. Loops were no problem. Video coming soon.

DeleteExcellent thanks for your prompt reply and flight testing for me also. Im only a total beginner in every aspect so may add ailerons at a later date when i am more comfortable. The only carbon fiber I have is a golf club that im going to use as the boom. CAn you suggest anything that i might substitute for the wing spar? With a new baby in the house im afraid cash is at a premium. Ha

DeleteFor the dihedral you will need about 200mm of aluminium tube bent to the desired angle, and you can probably get by without spars.

DeleteHi Andrew, your excellent videos are also well appreciated here in Germany.

ReplyDeleteYour slope soarer flies like a beauty. However, I was wondering if it is possible to simplify the design further to make the disassembled plane more compact when hiking. I am considering shortening the tail and leaving only a passive vertical fin while putting a v-mix on the ailerons. I am not sure though, if the relatively short cord length will then provide sufficient stability around the transversal axis. Does that sound promising to you?

I was also wondering what software you use to create these neat 3d drawings, is it free?

Thanks Nils. Slope soaring "planks" work very well so your idea sounds plausible. A longer chord and stubbier wing span might be the way to go.

DeleteThe 3D software is Google Sketchup and it is free. An amazing program

This comment has been removed by the author.

ReplyDeleteThanks for that design... This one recently got me up in the air... And it's so easy to fly... But I have one improvement for the tail. Had trouble, pulling it up from steep dives, cause the spring wasn't strong enough. So I set it up, that it pulls to positive and never had problems again.

ReplyDeleteParabéns pelo post, esse vai ser meu primeiro planador, vôo Aeromodelos motorizados mas como moro em montanha quero aproveitar ao máximo o hobby! Só não entendo como funciona o sistema de molas!

ReplyDeleteThanks for that. The springs are explained in the video, or you can try a rubber band return spring attached to a control horn on the opposite side.

DeleteCongratulations Andrew! simple construction and efficient, I live in Brazil and practical electric model airplanes, but due to the high cost of electronic models here in this country want to migrate to the gliders and probably will use this model as its base, a hug goodbye.

ReplyDeleteHello luuis, great comment and good luck, This is a wonderful slope soarer. Hugs from Australia

Deletethanks for the plans. just finished my build. where do you put the cg on your plane? keep the vidios coming! thanks southern California glider.

ReplyDeleteI think it was 50mm back. Great to hear you built one, good luck and share your video if you record some.

DeleteI'm new to torsion bars. What's the advantage of string over push rods, weight? Thanks !

ReplyDeleteJoe

Hey Joe. That's right, weight saving mainly, specially for light gliders. Removes all slop in the linkage too.

DeleteI finished my take on this plane the other day, and we were able to play catch with it in the yard to check CG today. It flew perfectly the first toss, and much better than expected. With a gentle throw it climbed a bit, and then just kept going. I had to run after it (after missing the catch). I'm hoping for some nice wind days to give it a go in an updraft.

ReplyDeleteI built mine with Dollar Tree foam board, and 9g metal geared servos throughout. A carbon arrow shaft for the tail boom. For power I used a 4cell aaa battery holder wired with a servo lead to plug into the Rx. With the battery pack shoved all the way into the nose the CG was dead on perfect.

Thank you for sharing your plans. It was a super easy build, and I am excited to get it to a slope!