Wingspan - 775mm

Wingspan - 775mmFlying weight - 400g

The Flite Test version is made from cheap US foamboard, which is not available in Aus.

My arch enemy combat pilot Chris made one from 6mm depron covered with packing tape, and I made a hotwire version from XPS foam.

Initial streamer combat flights have been fantastic, very addictive. Chris is narrowly leading the scoreboard....for now.

I suspect our numbers will be growing rapidly judging by the comments from the audience on the day. Combat video coming soon.

We decided to standardise motors, ESCs and battery for matched performance.

Motor - Turnigy 2822/14 1450kV

ESC - 20 to 25A

Battery - 1300mAH

Prop - 7 to 8"

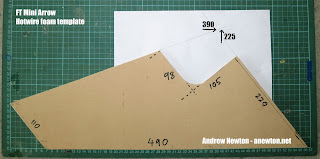

Hotwire templates (Right click and download)

Hotwire foam blank plan

(Same template with 2 different views)

Aileron and winglet templates

(6mm depron or 4mm coreplast)

Build overview

Maiden, repair and re-maiden

Mini Arrow streamer combat

Hey, Andrew, great build. One question: I've located an L-shaped aluminium piece from kitchen's cupboards, used to keep the side panels from delaminating when exposed to steam. It is 2mm thick, would that be thick enough to be used as motor mount or do I have to look for a thicker one?

ReplyDeleteI've also tought on using a couple of git cards glued together as motor mount, how about that?

Cheers and thanks for the fun.

Hello, yes 2mm should be perfect, mine are 1.6mm. I have one full gift card folded around the rear foam edge and glued with hot glue, then the aluminium is stuck on with strong double sided tape. Sounds like you're on the right track.

DeleteVery cool. I am starting to really love hot wire cutting. Thank you for sharing the templates!

ReplyDeleteExcellent, happy to hear it.

DeleteThanks for the template. Gonna build a mini arrow.

ReplyDeleteExcellent, let me know how it goes.

DeleteThanks for the template.. I'm about to build this..

ReplyDeleteHow did you find the Center of gravity?

Can this plane bring a gopro or is it to heavy?

No problem. CG was same as Flight Test design. Worked out right with the 2822 motor and 1300mAH battery. I dont have one just now but I'll find out for you. GoPro? Might be too big just have to try it.

DeleteThanks for the airfoil templates.

ReplyDeleteI liked my depron version of the Arrow.

Builds are in progress (already cut).

1 will be with motor, other one for slope soaring attempt at a rocky location (needs something tough & crash resistant).

Excellent, it will survive anything.

DeleteHey, I am building mini arrow atm, and noticed that smaller airfoil template is 14 cm length. On the foam board plans its 11 cm. So 3 centimeters of airfoil is sticking out. Is it normal?

ReplyDeleteYes that's right, it helps to have the template sticking out a bit so you can rest the hotwire before starting the cut.

DeleteHi Andrew Great Plan. I have been playing around with hotwire cutting of it. I'm not sucessful at it yet. I found a place near me that would gladly CNC hot wire cut the plans for me. I have a couple of questions, I hope you can answer it.

ReplyDeleteAirfoil: Clark Z

Root Chord: 284mm

Tip Chord: 109mm

Wingspan: 390mm each side

Setback: 303mm

Do I have this correct?

Hi Mark,

DeleteYes the measurements are correct.

But the airfoil started as Clark Z then I stretched it out a bit and thickened the trailing edge of the wingtip so it didn't end up too thin.

It is very tricky to cut with the taper and I always have to smooth out the cutting defects.

Good luck

thank you for the very quick reply. A machinist friend of mine made me some metal templates from your plans for the root and tip cords. I have been practicing on blue insulation foam, already went through a 4 feet by 8 feet section. Getting better, but just not there yet. I have a nice big block of epp foam sitting aside till I get it perfect. So for the meantime I was going to have someone just cnc it for me.

Deleteis this the sam clark z template you are using for you trainer ?

ReplyDeleteGreetings,

DeleteNot quite, this one has been stretched and thickened at the trailing edge or the wing tip.

the small template has 14cm of length and the small part of my wing has about 11,5 cm, is that correct?

ReplyDeleteYes that's right, templates are longer than the final wing size. Just trim off the trailing edge after cutting

DeleteActually that's misleading sorry, the template is longer so you can rest the wire on the overhang before starting the cut.

Deleteok , thanks for the fast answer

Deletethis would be my first airplane to build , and my first airplane to fly, do you think its easy enough? i am 16 and i am want to enter to this hobby

ReplyDeleteI wouldn't recommend this as a plane to learn with. It's too fast and agile, but give it a go. You will learn quickly. It is tough and can handle crashes well.

DeleteI start in this hobby three years ago, and I try to build same planes and final drown plans myself and made a blog: http://www planesplans.blogspot.com. To help people to build wings I hab share your video that is wery helpfuly. Thunks

ReplyDeleteExcellent work on your blog, I'll follow you.

DeleteCan you help me I do not know where I made my mistake I also built a wing Also the airfoil with wire cut But took other forms Naca 2412 The wing accurses directly Or makes a looping I'll send you an example video https://youtu.be/ZNhrqjgy03c

ReplyDeletesorry for my bad English

Hello. Your wing looks nicely built.

DeleteMy first thought is that the ailerons are reversed.

Or it may be tail heavy - move the battery forward or add weight to the nose.

Let me know how you go and good luck.

Hello Andrew

ReplyDeleteI made a hot wire cut Mini Arrow as per your plans & recommendations, used your recommended Bunnings Foam, hot wire frame & $70 variable Power supply from China. I got an excellent result, although I am not overly keen on the Bunnings Foam as it very hard to get a smooth hot wire finish (I had 3 attempts)& the foam is very brittle.

The Mini Arrow flew perfectly from the 1st hand launch, I have upgraded the motor to a Turnigy 2826 - 2200 kv & it performs very very well although I an not impressed with the low speed handling (ClarkZ Airfoil) which is when I do damage on landing. I am making another using an MH70,12% Airfoil and using a much lighter foam.

Finally, I have all the Mini Arrow drawings in CAD & PDF format. If you want them please let me know.

Regards

Neil M

Canberra

Brilliant Neil, it would be a wild little beast with that motor. Let me know if your new airfoil works better. Would love the PDF drawings to have a look at thanks. apnewton@gmail.com

DeleteHello Neil would i be able to grab those drawing off you as well i would like to laser the airfoils out of ply so having your cad drawings would be awesome you can send them through at dursunmax@gmail.com please reply thanks!!

DeleteExcellent work! I will build one this weekend. Have you tried David windestål hot wire technique? https://youtu.be/R0ZCnR_g6ZU

ReplyDeleteDo you think it could work with this design?

Yes I have tried that method but it is not suitable because you have no control over the other end of the cut, it is just a scaled down version of the template. I wanted a different airfoil on the narrow end.

ReplyDeletePlease can you tell me if it carries the mini arrow some degrees of deflection in depth?

ReplyDeleteHello Andrew.I Like your jobs.where is the Centre of Gravity in the mini arrow please.I build one coming soon.Thanks.Best regards.

ReplyDelete